What are the hydraulic systems in ships?

Hydraulic systems in ships transform pressurized fluid into mechanical power, enabling vital operations. These systems ensure precise rudder control for high-speed navigation and heavy loads. They power deck machinery, facilitating seamless cargo handling. Submarines rely on marine hydraulics for stability, managing ballast tanks and rudders. Hydraulic motors paired with planetary gearboxes enhance winch efficiency on vessels.

Key Takeaways

- Hydraulic systems on ships use pressurized liquid to run key tasks. These include steering and moving cargo, which are vital for safe travel.

- Checking and maintaining hydraulic systems often stops problems and makes them last longer. This keeps them working well in tough sea conditions.

- New ideas like using AI and energy-saving designs are improving hydraulic systems. These changes make them work better and more eco-friendly.

Marine Hydraulics: Definition and Overview

What are hydraulic systems in ships?

Marine hydraulics refers to systems that use pressurized fluid to deliver power and torque for various ship operations. These systems are renowned for their ability to efficiently transfer large linear and rotary forces, making them indispensable in maritime applications. Hydraulic systems are commonly used for tasks such as steering, stabilizing, and operating deck machinery. They also play a crucial role in controlling adjustable pitch propellers, remotely operated valves, and thrusters.

The evolution of marine hydraulics highlights their growing importance. Early ships relied on manual winches, which demanded significant physical effort. The introduction of steam-powered winches in the 19th century reduced crew strain and increased lifting capacity. By the 20th century, electric winches improved efficiency and control. Modern hydraulic systems now offer high power-to-weight ratios, precise control, and remote operation capabilities, enhancing safety and reducing human error.

Key Features of Marine Hydraulic Systems:

- Types of Systems: Open, closed, and semi-closed hydraulic systems cater to different operational needs.

- Applications: Hydraulic systems power cranes, winches, stabilizers, steering machines, and platforms.

- Cooling and Filtration: Reliable operation depends on components like air filters, oil coolers, and high-pressure filters.

- Monitoring Tools: Gauges, alarms, and sensors ensure optimal performance.

| Aspect | Details |

|---|---|

| Definition | Marine hydraulics is a power and torque delivery system known for its efficient transfer of large linear and rotary forces. |

| Applications | - Rotary and linear operation of cranes |

- Rotary operation of winches

- Operation of stabilizers

- Steering machines

- Hydraulic bow and stern thrusters

- Adjustable pitch propellers

- Remotely operated valves

- Platforms and passerelles |

- | Types of Systems | – Open hydraulic systems

- Closed hydraulic systems

- Semi-closed hydraulic systems |

| Common Components | – Hydraulic oils - Hydraulic reservoir

- Filters

- Valves (directional, pressure, flow, proportional)

- Hydraulic pumps and motors

- Hydraulic cylinders

- Installation and maintenance |

| Cooling and Filtration | Essential for system reliability; includes air filters, high-pressure filters, return filters, and oil coolers. |

| Information Systems | Includes oil level and temperature gauges, alarms, and pressure sensors for monitoring.

How do hydraulic systems work in a marine environment?

Marine hydraulic systems operate by pressurizing fluid, typically oil, to generate mechanical power. This pressurized fluid flows through pipes and hoses to actuators, motors, or cylinders, which convert the energy into motion. The system’s design ensures smooth operation even under challenging conditions, such as high humidity, saltwater exposure, and extreme temperatures.

Hydraulic systems in ships rely on several key components to function effectively:

- Hydraulic Pumps: These create the necessary pressure to move fluid through the system.

- Valves: Directional, pressure, and flow control valves regulate fluid movement and ensure precision.

- Reservoirs: These store hydraulic fluid and maintain system pressure.

- Cooling Systems: Oil coolers and filters prevent overheating and contamination.

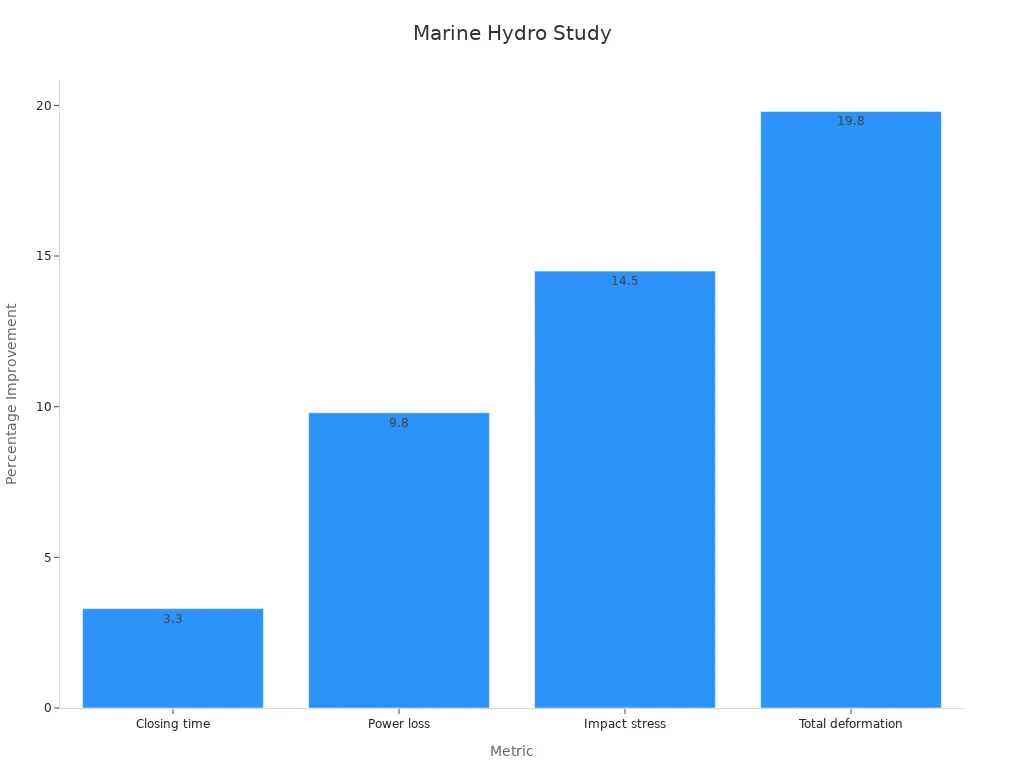

Recent engineering studies have optimized hydraulic systems for marine applications. For example, underwater hydraulic manipulators (UHMs) and water hydraulic systems have seen significant advancements. Multi-objective optimization techniques have improved performance metrics, including reducing power losses and impact stress. The chart below illustrates these improvements:

Advantages of Marine Hydraulic Systems:

- High power-to-weight ratio for efficient operation.

- Precise control for complex tasks like steering and stabilization.

- Remote operation capabilities enhance safety and reduce human error.

Marine hydraulics have revolutionized ship operations, enabling centralized control of cargo handling, deck machinery, and maneuvering systems. Their adaptability and reliability make them a cornerstone of modern maritime engineering.

Key Components of Marine Hydraulic Systems

Hydraulic pumps and motors

Hydraulic pumps and motors form the backbone of marine hydraulics. Pumps generate the pressure required to move fluid through the system, while motors convert this energy into mechanical motion. Positive-displacement pumps, such as gear, vane, and piston types, are commonly used due to their efficiency and reliability. ISO standards, including ISO 4409:2007 and ISO 8426, outline testing methods for these components, ensuring their performance meets industry benchmarks. Real-world testing evaluates discharge characteristics and torque performance, providing critical data for optimizing efficiency.

Technological advancements have further enhanced hydraulic pumps and motors. Energy-efficient designs reduce power consumption, while smart features improve operational reliability. Marine hydraulic pumps are recognized for their durability, offering long service life and minimizing replacement demand. These innovations make them indispensable in ship operations, from steering systems to deck machinery.

Hydraulic fluid and reservoirs

Hydraulic fluid serves as the medium for power transmission in marine hydraulic systems. It must possess properties like high viscosity, thermal stability, and resistance to corrosion. Reservoirs store this fluid, maintaining system pressure and preventing contamination. Proper fluid management is essential to ensure system efficiency and longevity.

Marine environments demand specialized hydraulic fluids that can withstand extreme temperatures and saltwater exposure. Regular monitoring of fluid levels and quality prevents system failures. Filters integrated into reservoirs remove impurities, while cooling systems regulate fluid temperature, ensuring optimal performance.

Valves, actuators, and manifolds

Valves, actuators, and manifolds control fluid flow and direction within hydraulic systems. Valves regulate pressure and flow, while actuators convert hydraulic energy into mechanical motion. Manifolds distribute fluid to various components, enabling complex operations. Performance validation tests assess the reliability of these components, measuring leakage and stroke time. Failure mode analysis has improved valve reliability significantly, reducing operational risks.

| Assessment Type | Findings |

|---|---|

| Performance Validation Tests | Demonstrated reliability through tests on air-operated valves, measuring leakage and stroke time. |

| Failure Mode Analysis | Identified major causes of failure in valves, improving reliability from 34.2% to 84.2%. |

| FMEA of Butterfly Valves | Compared reliability of manually and electrically operated valves, highlighting design implications. |

These components ensure precise control, making them vital for steering systems, stabilizers, and thrusters.

Pipes, hoses, and fittings

Pipes, hoses, and fittings transport hydraulic fluid throughout the system. They must withstand high pressure and resist corrosion in marine environments. Flexible hoses allow movement in dynamic systems, while rigid pipes provide structural stability. Fittings connect these components, ensuring leak-free operation.

Durability and efficiency are critical for these elements. Regular inspections identify wear and tear, preventing system failures. Advanced materials, such as stainless steel and reinforced polymers, enhance their performance, ensuring reliability in demanding conditions.

Applications of Hydraulic Systems in Ships

Hydraulic systems play a pivotal role in the operation of ships, enabling critical functions that ensure safety, efficiency, and reliability. These systems are designed to handle demanding maritime conditions, making them indispensable in various shipboard applications.

Steering and maneuvering systems

Hydraulic systems are integral to a ship’s steering and maneuvering capabilities. They provide the force required to move the rudder, enabling precise control over the vessel’s direction. This is especially important for large ships, where manual steering would be impractical. Hydraulic steering systems are designed to operate smoothly under high loads, ensuring reliable performance even in rough seas.

Modern hydraulic steering systems often include redundancy features, such as dual pumps and circuits, to enhance safety. These systems also integrate with autopilot technology, allowing for automated navigation. By using marine hydraulics, ships achieve greater maneuverability, which is essential for docking, navigating narrow channels, and avoiding obstacles.

Stabilization systems

Stabilization systems rely on hydraulic technology to reduce the rolling motion of ships caused by waves. These systems improve passenger comfort and prevent cargo from shifting during transit. Hydraulic stabilizers, such as fin stabilizers, use actuators to adjust the angle of fins located beneath the waterline. This counteracts the force of waves, keeping the ship steady.

Hydraulic stabilization systems are highly responsive, adjusting in real-time to changing sea conditions. They are commonly used on cruise ships, ferries, and luxury yachts. The efficiency of these systems ensures that vessels maintain stability, even in turbulent waters, enhancing safety and operational performance.

Deck machinery and cargo handling

Hydraulic systems power a wide range of deck machinery, making cargo handling operations more efficient. Cranes, winches, and hatch covers all depend on hydraulic technology to perform heavy lifting and precise movements. These systems provide the high torque and power needed to handle large loads, reducing the time and effort required for loading and unloading cargo.

Marine hydraulics also enable the operation of specialized equipment, such as container spreaders and bulk cargo grabs. These tools are essential for modern shipping operations, where speed and accuracy are critical. Hydraulic systems ensure that deck machinery operates reliably, even under continuous use in harsh marine environments.

Mooring and anchoring systems

Mooring and anchoring systems are vital for securing ships at ports or offshore locations. Hydraulic windlasses and capstans provide the force needed to handle heavy anchor chains and mooring lines. These systems allow for precise control, ensuring that ships remain securely anchored or moored, even in strong currents or high winds.

Hydraulic mooring systems often include tension monitoring features, which help maintain optimal line tension. This prevents excessive strain on the equipment and reduces the risk of line failure. By utilizing hydraulic technology, these systems offer durability and efficiency, ensuring safe and reliable operations.

Maintenance and Operational Best Practices

Regular inspection and monitoring

Routine inspections ensure the reliability of marine hydraulic systems. Technicians should check for leaks, wear, and misalignments in pipes, hoses, and fittings. Monitoring tools, such as pressure gauges and temperature sensors, provide real-time data on system performance. These tools help identify potential issues before they escalate.

Tip: Establishing a checklist for daily, weekly, and monthly inspections can streamline the process and reduce oversight.

Visual inspections of hydraulic cylinders and actuators can reveal early signs of damage. Additionally, vibration analysis and thermal imaging can detect hidden faults in pumps and motors. Regular monitoring minimizes downtime and extends the lifespan of hydraulic components.

Hydraulic fluid management and replacement

Hydraulic fluid quality directly impacts system efficiency. Contaminated or degraded fluid can cause blockages, overheating, and component failure. Operators should regularly test fluid for viscosity, contamination, and water content.

- Best Practices for Fluid Management:

- Use filters to remove impurities.

- Maintain optimal fluid levels in reservoirs.

- Replace fluid according to manufacturer recommendations.

Marine environments demand fluids with high thermal stability and corrosion resistance. Proper fluid management ensures smooth operation and prevents costly repairs.

Preventive maintenance schedules

A structured maintenance schedule reduces the risk of unexpected failures. Tasks include cleaning filters, tightening fittings, and lubricating moving parts. Scheduling maintenance during non-operational periods minimizes disruptions.

Note: Preventive maintenance should align with the ship’s operational cycle and include detailed service logs for future reference.

Technicians should also update software in modern hydraulic systems to ensure compatibility with newer components. This proactive approach enhances system reliability.

Troubleshooting and resolving common issues

Effective troubleshooting requires a systematic approach. Service logs highlight successful methods for resolving common hydraulic problems:

- Resolving a Slipping Clutch: Inspect clutch plates, check hydraulic pressure, change hydraulic fluid, and test engagement settings.

- Fixing Hard or Delayed Shifting: Inspect hydraulic lines, flush the system, check control valve operation, and re-test.

- Solving Excessive Noise and Vibration: Inspect shaft alignment, check bearings and gears, secure fasteners, and conduct a test run.

- Addressing Overheating: Inspect heat exchanger, check oil levels, inspect cooling system flow, and monitor operating temperatures.

By addressing these issues promptly, operators can maintain system performance and avoid prolonged downtime.

Hydraulic systems play a vital role in ship operations, ensuring safety and efficiency in critical tasks like steering and cargo handling. Proper maintenance extends their lifespan and reliability. Emerging trends, such as AI integration and energy-efficient designs, continue to redefine marine hydraulics.

| Key Trend | Description |

|---|---|

| Integration of AI and IoT | Enhances efficiency and functionality of hydraulic systems in ship operations. |

| Focus on energy efficiency | Drives innovation in hydraulic systems to meet sustainability goals. |

| Strategic partnerships | Companies collaborate with tech providers to integrate advanced technologies into hydraulic systems. |

| Demand for automation | Increasing adoption of automation in industries, including shipping, enhances operational efficiency. |

| Sustainability focus | Hydraulic systems that promote energy efficiency and reduce environmental impact are gaining traction. |

Note: As technology evolves, hydraulic systems will continue to enhance the functionality and sustainability of modern ships.

FAQ

What are the advantages of hydraulic systems in ships?

Hydraulic systems offer high power-to-weight ratios, precise control, and durability. They enhance efficiency in steering, stabilization, and cargo handling, ensuring reliable performance under demanding maritime conditions.

How often should hydraulic systems be inspected?

Technicians should inspect hydraulic systems weekly for leaks, wear, and alignment issues. Regular monitoring ensures optimal performance and prevents costly downtime or unexpected failures.

Can hydraulic systems operate in extreme marine environments?

Yes, marine hydraulic systems are designed to withstand saltwater exposure, high humidity, and temperature extremes. Specialized components and fluids ensure reliable operation in harsh conditions.