Man Lifting Winch / Elevator Winch

Man lifting winch is one of a benchmark products of high-reliability proof. We have kept advancing clutch & braking system to empower our winch designs over 23 years. We are certified of designing and manufacturing diverse winches for a wide range of applications, including mining, pipe laying, oil exploiting, scientific research drilling, military, dredging and shipyard industries. We have exported this type reliable elevator winch, which used in ship for both person and cargo lifting solutions, in North American. It has obtained good reputation from our customers. Its enormous potential can be discovered in other fields too.

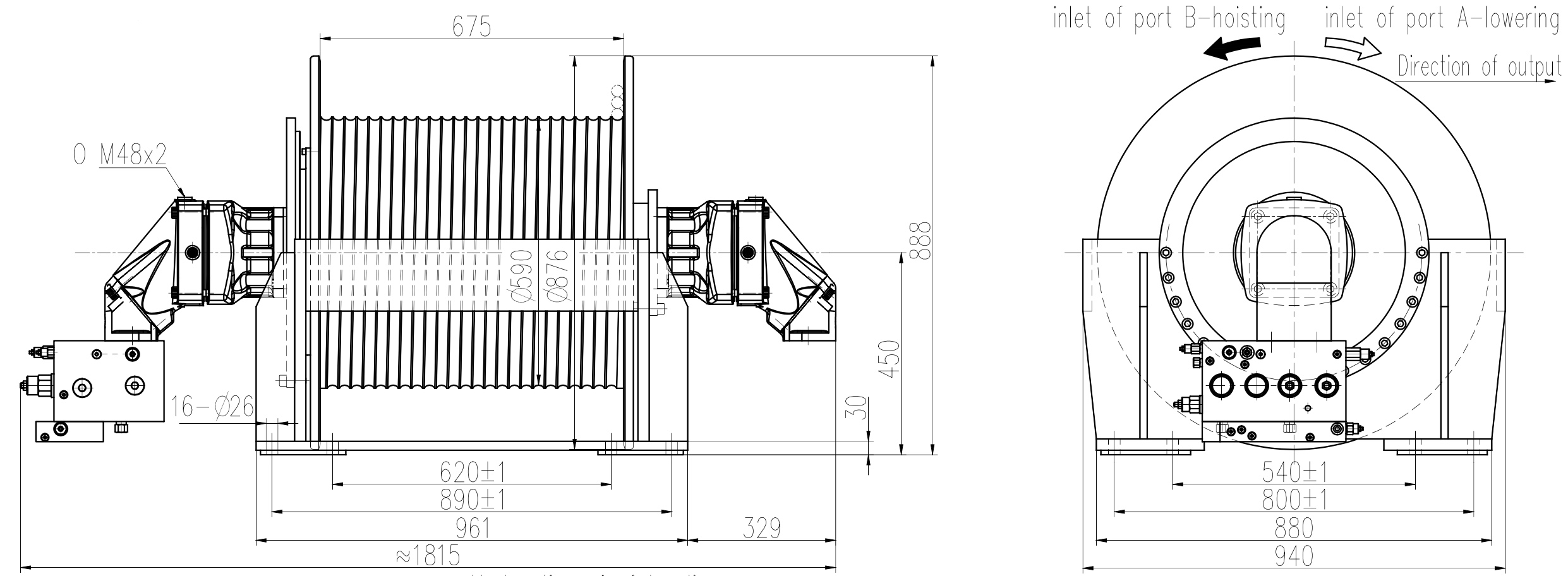

Mechanical Configuration: The winch consists of two hydraulic motors, one planetary gearbox, two multi-disc brakes, valve blocks, drum and frame. Customized modifications are available at any moment.

The Winch’s Main Parameters:

| Working Condition |

Carry Cargo |

Man Riding |

| Rated Pull at the 3rd Layer (t) |

13 |

2 |

| Max Line Pull at the 3rd Layer (t) |

14 |

2.5 |

| Rated System Pressure (Bar) |

280 |

60 |

| Max System Pressure (Bar) |

300 |

70 |

| Speed of Cable Wire at the 3rd Layer (m/min) |

120 |

|

| Total Displacement (mL/r) |

13960 |

|

| Pump Supply Oil Flow (L/min) |

790 |

|

| Diameter of Care Wire (mm) |

26 |

|

| Layer |

3 |

|

| Drum Capacity of Care Wire (m) |

150 |

|

| Hydraulic Motor Model |

F12-250×2 |

|

| Gearbox Model (Ratio) |

B27.93 |

|

| Static Brake Holding Force at the 3rd Layer (t) |

19.5 |

|

| Dynamic Brake Holding Force at the 3rd Layer(t) |

13 |

|

| High Speed Stage Brake Torque (N.m) |

2607 |

|

| Low Speed Stage Brake Torque (N.m) |

50143 |

|

| Brake Control Pressure (Bar) |

>30, <60 |

|

Man Lifting Winch / Elevator Winch Related Video: