5 Key Advantages of Hydraulic Mooring Winches: Why Replace Electric Winches?

Hydraulic Mooring Winches are increasingly preferred for their superior performance in demanding marine environments. Understanding the compelling reasons to choose a Hydraulic Mooring Winch over electric alternatives is crucial for operational efficiency and safety. This post details the five key advantages making them a superior choice.

Key Takeaways

- Hydraulic winches offer more power and pull heavier loads than electric winches. They work well even with big jobs.

- Hydraulic winches are built strong for tough ocean conditions. They last longer and break down less often than electric winches.

- Hydraulic winches give you better control and are safer to use. They have features that prevent too much weight and reduce fire risks.

Superior Power and Torque Delivery of Hydraulic Mooring Winches

Consistent Performance Under Heavy Loads

Hydraulic systems consistently deliver power, maintaining their output even when facing significant resistance. A 30-ton (60,000 lbs) Hydraulic Mooring Winch handles substantial loads with ease. Another common size is the 15-ton (30,000 lbs) hydraulic mooring winch. While an electric mooring winch can have a carrying capacity of 35 tons (70,000 lbs), hydraulic systems often dominate the higher end of heavy-duty applications. Consider the typical load capacities:

| Winch Type | Category | Load Capacity (lbs) |

|---|---|---|

| Electric | Light-Duty | Up to 6,000 |

| Electric | Mid-Duty | 2,000 to 12,000 |

| Electric | Heavy-Duty | 12,000 to 20,000 |

| Hydraulic | Heavy-Duty | 10,000 to 50,000 |

| Hydraulic | Industrial | 50,000 and above |

| Hydraulic | Marine | 20,000 to 100,000 |

This table clearly shows hydraulic winches are designed for much heavier tasks. They provide reliable power delivery under continuous stress.

Enhanced Pulling Capacity for Demanding Operations

Hydraulic systems provide superior pulling force for demanding marine operations. They generate immense torque, which is essential for moving large vessels or heavy equipment. A Hydraulic Mooring Winch, such as a 45-ton marine model, offers a line pull capacity of 40 tons (392 KN). In contrast, electric mooring winches typically offer lower maximum pulling loads. For instance, an electric 1200 CLR model has a maximum pulling load of 600 kg (1320 lb), and a 2500 CLR model reaches 1250 kg (2750 lb). This significant difference in pulling power makes hydraulic winches the preferred choice for critical mooring tasks. They ensure efficient and safe handling of heavy loads.

Unmatched Durability and Reliability of Hydraulic Mooring Winches

Robust Design for Harsh Marine Environments

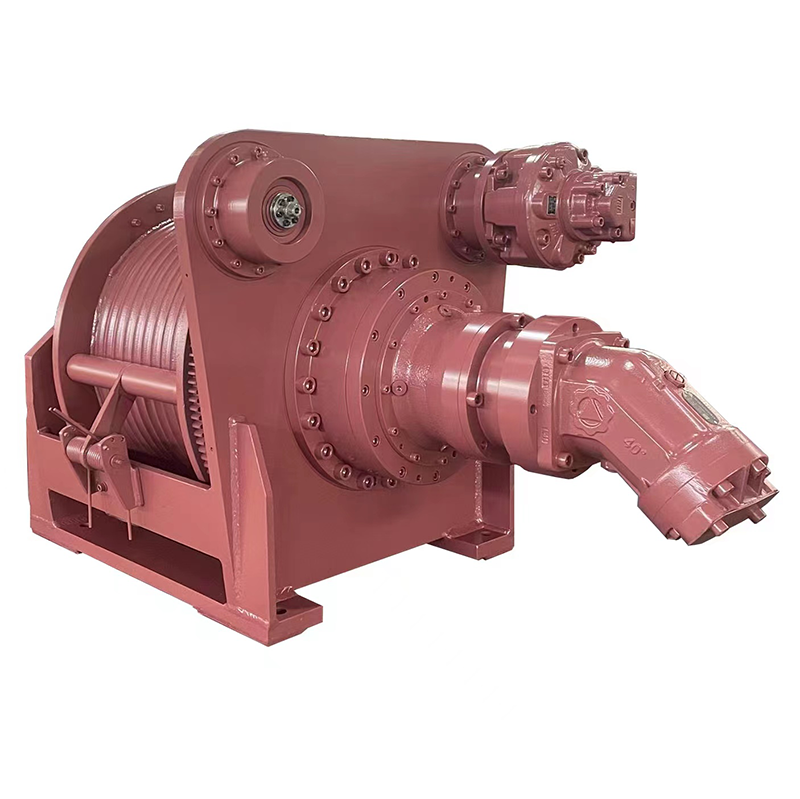

Hydraulic mooring winches feature robust designs. They withstand the harsh marine environment effectively. Manufacturers use corrosion-resistant materials in general winch construction. They also apply saltwater-proof coatings. These coatings protect components from the corrosive effects of seawater. The drum, a critical component, consists of high-strength steel. This material ensures durability under extreme loads and continuous operation. Such construction minimizes wear and tear. It also extends the winch’s operational life. This inherent toughness makes hydraulic winches ideal for continuous use in demanding maritime conditions. Their construction prioritizes longevity and resistance to environmental stressors, ensuring consistent performance over many years. This robust engineering translates directly into fewer breakdowns and a longer service life for the equipment.

Reduced Risk of Electrical System Failures

Hydraulic systems inherently reduce the risk of electrical system failures. They do not rely on complex electrical circuits or sensitive electronic components. This absence makes them less susceptible to water ingress, humidity, and corrosion. These factors commonly plague electrical systems in marine settings. A Hydraulic Mooring Winch operates reliably without the vulnerabilities of exposed wiring or circuit boards. This design choice enhances overall system reliability. It also ensures consistent performance during critical mooring operations. The simplicity of hydraulic power transmission contributes significantly to its long-term dependability, minimizing unexpected downtime. Operators benefit from fewer electrical faults and a more stable system, especially in adverse weather conditions where electrical components are most vulnerable. This fundamental difference provides a significant advantage in marine applications, where environmental conditions constantly challenge electrical integrity.

Precise Control and Smooth Operation with Hydraulic Mooring Winches

Variable Speed and Fine Adjustment Capabilities

Hydraulic systems offer operators exceptional control over winch operations. They provide variable speed capabilities, allowing for precise adjustments during critical mooring procedures. Operators can smoothly increase or decrease line speed, ensuring gentle handling of mooring lines and accurate vessel positioning. This fine adjustment capability minimizes sudden jerks or excessive strain on equipment and mooring points. The direct relationship between hydraulic fluid flow and motor speed enables seamless transitions. This precision is vital for safely securing vessels of all sizes, especially in challenging weather conditions or tight docking spaces.

Responsive and Secure Braking Systems

Hydraulic Mooring Winches feature highly responsive and secure braking systems. These systems ensure immediate stopping power and reliable load holding. The inherent design of hydraulic brakes provides consistent performance, even under maximum load. This reliability is crucial for preventing accidental line slippage and maintaining vessel stability. Manufacturers integrate several robust braking mechanisms into these winches. These include:

- Manual brake systems for direct operator engagement.

- Hydraulic brake systems that offer powerful, controlled deceleration.

- Drive failure braking protection systems, which automatically engage in case of power loss.

These combined features enhance operational safety and provide operators with confidence during demanding mooring tasks.

Simplified Maintenance and Extended Longevity of Hydraulic Mooring Winches

Fewer Complex Electrical Components to Manage

Hydraulic systems inherently simplify maintenance procedures. They contain significantly fewer complex electrical components compared to electric winches. Operators do not manage intricate wiring harnesses, sensitive circuit boards, or numerous sensors. This design reduces potential points of failure. Troubleshooting becomes more straightforward. Technicians can often diagnose issues visually or with basic pressure gauges. This simplicity translates into less time spent on repairs. It also lowers the need for specialized electrical expertise. The absence of delicate electronics makes these systems more resilient in harsh marine environments. This fundamental difference streamlines routine checks and reduces the likelihood of unexpected electrical malfunctions, contributing to overall operational efficiency.

Extended Service Life of Core Components

Hydraulic components are renowned for their exceptional durability and long operational life. The hydraulic fluid itself acts as a lubricant and coolant. This dual function significantly reduces friction and heat within the system. It protects critical parts like pumps, motors, and cylinders from premature wear. Manufacturers construct these core components from robust, high-strength materials. This ensures they withstand continuous heavy-duty operation and extreme loads. A well-maintained Hydraulic Mooring Winch often provides decades of reliable service. This extended longevity minimizes replacement costs and reduces downtime for vessel operators. INI Hydraulic specializes in designing and manufacturing durable hydraulic components, ensuring long-term performance for their winches. Their expertise contributes directly to the extended service life of these critical systems, offering a strong return on investment.

Enhanced Safety Features of Hydraulic Mooring Winches

Integrated Overload Protection Mechanisms

Hydraulic mooring winches incorporate robust safety features. These include integrated overload protection mechanisms. This key safety feature prevents the winch from exceeding its rated capacity. It avoids mechanical failure. Load monitoring systems provide real-time feedback on tension and weight distribution. These systems utilize sensors to gauge line tension. They alert operators when the load approaches hazardous levels. Their primary function is to prevent the winch from attempting to handle loads beyond its capacity. Many hydraulic marine winches incorporate these features. This mechanism ensures the winch either automatically adjusts its operation or ceases function when its maximum capacity is reached. This prevents equipment damage and safeguards personnel and cargo. Brake render testing is a critical safety mechanism for hydraulic mooring winches. It involves establishing predefined tension levels. At these levels, the winch brakes automatically release the line. This action prevents system overload during environmental stress. It protects the entire mooring system from catastrophic failure. It also maintains vessel position during normal operations.

Reduced Fire Hazard Compared to Electric Systems

Hydraulic systems inherently present a reduced fire hazard. They do not rely on electrical currents or complex wiring. This design eliminates the risk of electrical sparks or short circuits. These are common ignition sources in marine environments. Hydraulic fluid, often non-flammable, circulates within a closed system. This further minimizes fire risks. The absence of high-voltage electrical components contributes to a safer operational environment. Operators gain peace of mind. This fundamental safety advantage makes hydraulic mooring winches a preferred choice for critical marine applications.

Why Hydraulic Mooring Winches Outperform Electric Winches

Overcoming the Limitations of Electric Systems

Hydraulic mooring winches effectively overcome the inherent limitations of electric systems. Electric winches often struggle with the harsh marine environment. Their complex electrical components are susceptible to water ingress, corrosion, and temperature fluctuations. These factors lead to frequent breakdowns and increased maintenance. Hydraulic systems, in contrast, feature a sealed design. This design protects internal components from environmental damage. They operate reliably in extreme conditions. This robustness ensures consistent performance. It also minimizes unexpected downtime. The simpler power transmission of hydraulics avoids the intricate wiring and sensitive electronics of electric winches. This fundamental difference enhances overall system resilience.

Long-Term Operational Cost Savings and Efficiency Gains

Investing in hydraulic mooring winches yields significant long-term operational cost savings and efficiency gains. Their robust construction and fewer complex electrical parts translate into reduced maintenance requirements. Operators spend less time and money on repairs and replacements. The extended service life of hydraulic components, often decades, further lowers total ownership costs. INI Hydraulic’s expertise in durable hydraulic components ensures this longevity. Consistent power delivery and precise control also enhance operational efficiency. Vessels can moor more quickly and safely. This efficiency minimizes port time. It also optimizes vessel schedules. These combined benefits make hydraulic winches a financially sound and operationally superior choice.

Hydraulic Mooring Winches offer significant operational advantages. They directly address the challenges electric systems face. Their benefits in power, durability, control, maintenance, and safety strongly support their adoption. Investing in a Hydraulic Mooring Winch enhances vessel safety. It also improves operational efficiency and ensures greater longevity.

FAQ

Why do hydraulic winches offer superior power?

Hydraulic systems deliver consistent power. They maintain output under heavy loads. This ensures enhanced pulling capacity for demanding marine operations.

How do hydraulic winches ensure durability in harsh environments?

Manufacturers use robust designs and corrosion-resistant materials. This protects components from saltwater. It ensures long-term performance and minimizes wear.

What safety benefits do hydraulic winches provide?

They integrate overload protection. This prevents mechanical failure. They also reduce fire hazards compared to electrical systems.