Exploring the Applications and Benefits of Planetary Gearboxes in 2025

Planetary gearboxes have become essential in modern industries. You see them driving efficiency and precision in everything from robotics to renewable energy systems. Their compact design and high torque transmission make them indispensable. Innovations like the IGT180 gearbox and Bulldozer reducer showcase their versatility. By 2025, models like the Planetary Gearbox- IGT220T3 will redefine industrial performance.

Key Takeaways

- Planetary gearboxes are small and work well, perfect for robots, electric cars, and green energy systems.

- Their special design gives strong power and saves energy, cutting costs and helping the environment.

- By 2025, better materials and smart tech will improve how planetary gearboxes work and fit different industry needs.

What Is a Planetary Gearbox and How Does It Work?

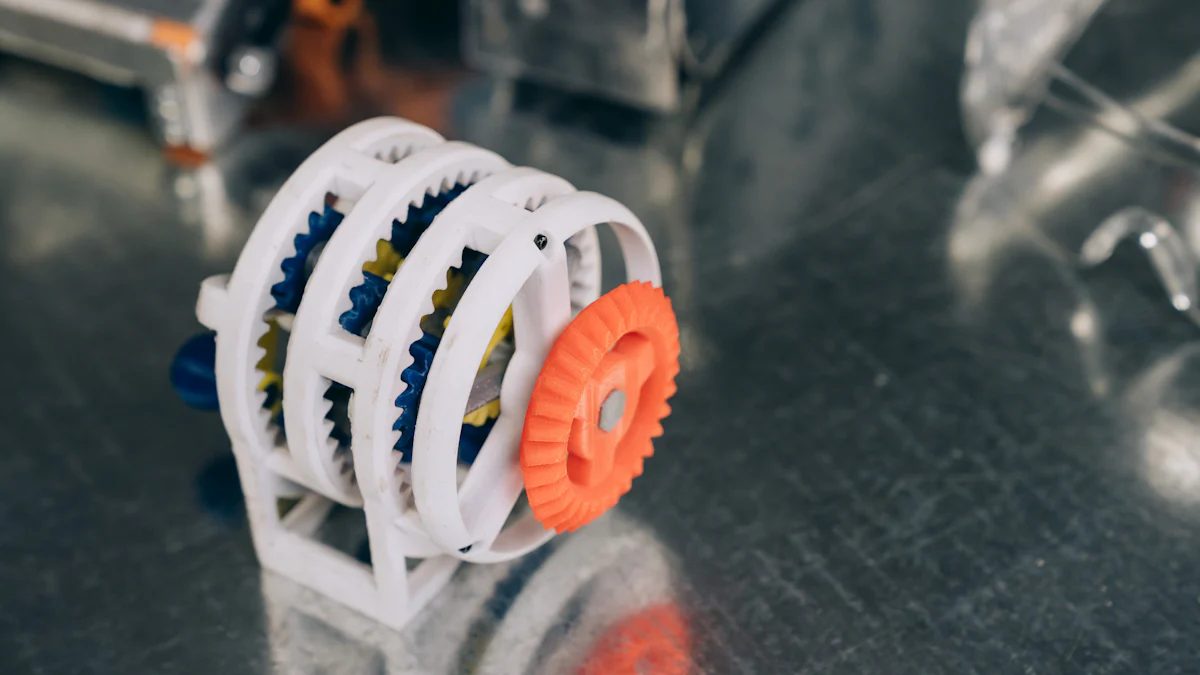

Overview of planetary gearbox design and components

A planetary gearbox consists of three main components: the sun gear, planet gears, and a ring gear. The sun gear sits at the center, while the planet gears revolve around it. These planet gears are held in place by a carrier, which connects them to the output shaft. The ring gear surrounds the planet gears and has internal teeth that mesh with them. This design creates a compact and efficient system for transmitting power. You’ll often find planetary gearboxes in applications where space is limited but high torque is required.

Tip: The unique arrangement of gears in a planetary gearbox allows it to distribute load evenly, reducing wear and tear.

Explanation of the working principles

The planetary gearbox works by transferring power from the input shaft to the output shaft through its gear system. When the sun gear rotates, it drives the planet gears, which in turn rotate within the ring gear. Depending on the configuration, the gearbox can increase torque, reduce speed, or both. This versatility makes it ideal for various industries. You can adjust the gear ratio by changing the size of the gears, which allows for precise control over performance.

Key features that distinguish planetary gearboxes from other types

Planetary gearboxes stand out due to their compact size and high power density. They can handle heavy loads while maintaining efficiency. Their design ensures smooth operation with minimal vibration. Unlike other gear systems, planetary gearboxes offer multiple gear ratios in a single unit. This flexibility makes them suitable for demanding applications like robotics, wind turbines, and electric vehicles.

Note: The durability of planetary gearboxes ensures a long service life, even under extreme conditions.

Benefits of Using a Planetary Gearbox

Compact size and space-saving design

You’ll appreciate how a planetary gearbox fits into tight spaces without compromising performance. Its compact design makes it ideal for applications where space is limited, such as robotics or electric vehicles. The arrangement of the sun, planet, and ring gears allows for a high power-to-size ratio. This means you can achieve powerful torque transmission in a smaller footprint compared to other gear systems.

High power density and torque transmission

A planetary gearbox delivers exceptional power density. It handles heavy loads while maintaining efficiency. The unique gear arrangement ensures even load distribution, which reduces stress on individual components. This feature makes it perfect for demanding tasks like lifting heavy machinery or powering wind turbines.

Efficiency and energy savings

You’ll notice significant energy savings when using a planetary gearbox. Its design minimizes energy loss during operation. The smooth transfer of power between gears ensures high efficiency, which is crucial for industries focused on sustainability. By reducing energy consumption, you can lower operational costs and contribute to a greener future.

Precision and reliability in demanding applications

Precision is a hallmark of planetary gearboxes. Their design ensures accurate motion control, which is essential in robotics and automation. You can rely on them for consistent performance, even in high-stress environments. This reliability makes them a trusted choice for industries like aerospace and medical devices.

Durability and long service life

A planetary gearbox is built to last. Its robust construction withstands extreme conditions, including high temperatures and heavy vibrations. Regular maintenance ensures a long service life, making it a cost-effective solution for industrial applications. You can depend on its durability to keep your operations running smoothly.

Applications of Planetary Gearboxes in Modern Industries

Use in automotive and electric vehicles

You’ll find planetary gearboxes playing a critical role in the automotive industry. They are essential in automatic transmissions, where they help manage speed and torque efficiently. Electric vehicles (EVs) also rely on planetary gearboxes to optimize power delivery from the motor to the wheels. Their compact design and ability to handle high torque make them ideal for EVs, where space and efficiency are priorities. By using a planetary gearbox, manufacturers can improve vehicle performance while reducing energy consumption.

Role in robotics and automation systems

Robotics and automation systems demand precision and reliability. A planetary gearbox ensures smooth and accurate motion control, which is vital for robotic arms and automated machinery. You’ll notice their use in applications requiring high torque in a small package, such as robotic joints or conveyor systems. Their durability and efficiency make them a trusted choice for industries aiming to enhance productivity.

Applications in renewable energy, such as wind turbines

Planetary gearboxes are indispensable in renewable energy systems, especially wind turbines. They help convert the slow rotational speed of turbine blades into the high-speed rotation needed to generate electricity. Their robust design withstands harsh environmental conditions, ensuring consistent performance. By using a planetary gearbox, you can maximize energy output and contribute to sustainable energy solutions.

Emerging uses in aerospace and defense sectors

The aerospace and defense industries increasingly adopt planetary gearboxes for their advanced machinery. You’ll see them in aircraft systems, where they provide precise control and high torque in a lightweight design. Defense applications, such as military vehicles and missile systems, also benefit from their reliability and compactness. These industries value the gearbox’s ability to perform under extreme conditions.

Anticipated applications in agricultural machinery and medical devices by 2025

By 2025, you can expect planetary gearboxes to revolutionize agricultural machinery and medical devices. In agriculture, they will enhance the efficiency of equipment like tractors and harvesters, enabling better performance in smaller, more efficient designs. In medical devices, their precision and compact size will support innovations in surgical robots and diagnostic equipment. These advancements will open new possibilities for both industries.

Innovations in Planetary Gearbox Technology by 2025

Advancements in materials and manufacturing techniques

By 2025, you’ll see planetary gearboxes benefiting from cutting-edge materials and manufacturing methods. Engineers are exploring lightweight composites and advanced alloys to improve strength without adding bulk. These materials reduce wear and extend the lifespan of the gearbox. Additive manufacturing, like 3D printing, is also revolutionizing production. It allows for precise designs and faster prototyping. This innovation ensures that planetary gearboxes meet the demands of modern industries with greater efficiency.

Integration with smart technologies and IoT

Smart technologies are transforming how you interact with machinery. Planetary gearboxes are no exception. By integrating sensors and IoT connectivity, these gearboxes can monitor their own performance in real time. You’ll receive alerts for maintenance needs or potential issues before they escalate. This predictive maintenance reduces downtime and improves productivity. Smart gearboxes also allow for remote monitoring, giving you greater control over operations from anywhere.

Focus on sustainability and energy efficiency

Sustainability is a priority for industries worldwide. Planetary gearboxes are evolving to meet this challenge. Manufacturers are designing gearboxes that consume less energy while delivering the same performance. Improved lubrication systems and friction-reducing materials contribute to this efficiency. By choosing energy-efficient gearboxes, you can lower your carbon footprint and operational costs simultaneously.

Customization for specific industrial needs

Every industry has unique requirements. By 2025, you’ll find planetary gearboxes tailored to specific applications. Whether it’s a compact design for medical devices or a high-torque model for wind turbines, customization ensures optimal performance. Manufacturers are using modular designs to make this possible. You can select components that match your exact needs, creating a solution that’s both efficient and cost-effective.

Planetary gearboxes play a vital role in modern industries. Their compact design, high efficiency, and precision make them indispensable across diverse applications.

- You’ll see them powering electric vehicles, robotics, and renewable energy systems.

- Their durability ensures long-term reliability in demanding environments.

Looking ahead: By 2025, advancements in materials, smart technologies, and customization will unlock even greater potential for innovation.

Planetary gearboxes will continue driving progress and efficiency in the years to come.

FAQ

What industries benefit the most from planetary gearboxes?

Planetary gearboxes are widely used in automotive, robotics, renewable energy, aerospace, and medical industries. Their compact design and high efficiency make them versatile across applications.

How do planetary gearboxes improve energy efficiency?

Their design minimizes energy loss during operation. Smooth power transfer and advanced materials reduce friction, helping you save energy and lower operational costs.

Can planetary gearboxes handle extreme conditions?

Yes, they can. Their robust construction withstands high temperatures, heavy vibrations, and harsh environments, ensuring reliable performance in demanding applications like wind turbines or defense systems.

Tip: Regular maintenance extends the lifespan of planetary gearboxes, even in extreme conditions.