Innovative Hydraulic Motor Solutions for Europe’s Boat Industry

Europe’s boat industry is adopting innovative hydraulic motor technologies to address key challenges in efficiency, sustainability, and performance. These advancements feature high-speed hydraulic motors and hydraulic drive motors, enhancing steering precision and vessel control. Eco-friendly solutions, like ini Hydraulic Motors, significantly lower greenhouse gas emissions by up to 30% throughout a vessel’s lifespan, highlighting their environmental advantages.

Key Takeaways

- Hydraulic motors help boats work better and use less fuel. They cut harmful gas emissions by up to 30%.

- Using green hydraulic fluids and systems protects nature and follows rules.

- Smart hydraulic systems with IoT make boats run smoother. They allow real-time checks and fix problems before they happen.

Hydraulic Motors in the Boat Industry

Role in Marine Applications

Hydraulic motors play a pivotal role in marine applications by delivering reliable power and precision for various operations. Their compact design and corrosion-resistant properties make them ideal for harsh marine environments. These motors drive essential components such as cylinders and claw clamps, enabling tasks like deep-sea exploration, resource development, and underwater research.

Hydraulic motors are indispensable for marine manipulators, offering high-pressure resistance and adaptability to diverse conditions. Translational grippers and four-finger bites enhance their functionality, ensuring efficient performance in challenging underwater scenarios.

| Feature | Description |

|---|---|

| Design | Hydraulic manipulator for deep-sea operations |

| Functionality | Drives the cylinder and claw clamp module to rotate |

| Applications | Marine exploration, research, and resource development |

| Characteristics | Compact structure, corrosion resistance, high-pressure resistance |

| Gripper Types | Translational and four-finger bites, adaptable for various conditions |

Common Types and Their Functions

Hydraulic motors come in various types, each tailored to specific marine applications. High-speed motors excel in quick-response scenarios, while low-speed motors provide high torque for heavy-duty tasks. Radial plunger motors deliver reliable performance in low-speed, high-torque applications, making them ideal for marine propulsion systems. Axial plunger motors offer adjustable speed and torque control, ensuring versatility across different marine operations.

Type of Hydraulic Motor |

Characteristics |

Applications in Marine Settings |

|---|---|---|

| High-speed Hydraulic Motors | Output speed of 500 rpm and above, low rotational inertia, fast start-up | Suitable for applications requiring quick response but low torque |

| Low-speed Hydraulic Motors | Output speed below 500 rpm, large displacement | Ideal for heavy-duty applications requiring high torque |

| Gear Motors | Balanced design, small size, but high noise | Less common in marine due to torque ripple issues |

| Vane Motors | Small size, low moment of inertia, but large leakage | Suitable for high-speed applications with low torque |

| Radial Plunger Motors | High torque, reliable performance | Effective in low-speed, high-torque marine applications |

| Axial Plunger Motors | Variable torque and speed based on swash plate angle | Versatile for adjustable speed and torque control |

Advancements in Hydraulic Systems

Recent advancements in hydraulic systems have revolutionized their performance in the boat industry. Compact and lightweight designs simplify installation and enhance maneuverability. Enhanced load capacity allows hydraulic winches to handle heavier loads efficiently, while precise control systems reduce human error during operations. Modern safety features, such as overload protection and emergency stop functions, ensure secure handling in critical situations.

- Remote Control and Monitoring: Operators can manage hydraulic systems from a distance, improving safety in hazardous environments.

- Integration with Telemetry Systems: Centralized control and data exchange optimize performance and streamline operations.

These innovations demonstrate the industry’s commitment to improving efficiency, safety, and automation in marine hydraulic systems.

Challenges Facing Europe’s Boat Industry

Environmental Regulations and Sustainability

Europe’s boat industry faces mounting pressure to comply with stringent environmental regulations. These regulations aim to reduce emissions and promote sustainability but often lead to increased production costs. Manufacturers report a 15-20% rise in overall costs due to compliance requirements. Additionally, older vessels struggle to meet modern emission standards, which negatively impacts their resale value.

Challenge |

Impact |

|---|---|

| Stringent environmental regulations | Contribute to increased production costs for manufacturers, estimated at 15-20% overall. |

| Compliance costs | Necessitate costly upgrades or replacements, limiting affordability and market expansion. |

| Technological advancements | Required to meet modern emission standards, affecting older boats’ resale value. |

The European Maritime Transport Environmental Report 2025 highlights the sector’s progress toward sustainability. It emphasizes the importance of tools like the FuelEU Maritime Regulation and the EU Emissions Trading System to achieve environmental goals. However, the report also underscores the need for increased efforts to address these challenges effectively.

Energy Efficiency and Fuel Consumption

Energy efficiency remains a critical concern for Europe’s marine sector. Rising fuel costs and the push for greener operations compel manufacturers to develop energy-efficient technologies. Hydraulic motors, known for their high efficiency, play a pivotal role in reducing fuel consumption. Advanced designs, such as two-speed and switchable displacement motors, optimize energy use by adapting to varying operational demands. These innovations not only lower operational costs but also contribute to a reduced environmental footprint.

Performance Demands in Marine Environments

Marine environments demand robust and reliable equipment capable of withstanding extreme conditions. Hydraulic motors, including IP69K-certified models, are engineered to meet these challenges. They undergo rigorous testing, such as hydrostatic pressure and endurance tests, to ensure durability and performance. For instance:

- Sundstrand piston pumps operated for 450 hours, exceeding standard durations.

- Eaton-Vickers vane pumps maintained integrity after 1,000 hours of testing.

- High-temperature tests at 250°F confirmed consistent hydraulic fluid performance.

These benchmarks demonstrate the industry’s commitment to delivering high-performance solutions that meet the rigorous demands of marine applications.

Innovative Hydraulic Motor Solutions

High-Efficiency Hydraulic Motors

High-efficiency hydraulic motors are transforming marine applications by delivering superior performance and energy savings. These motors are designed for heavy-duty operations, offering high torque and power output while minimizing fuel consumption. Models like the MHP20 series feature modular designs that allow customization for specific needs.

Specification |

Value |

|---|---|

| Series | MHP20 |

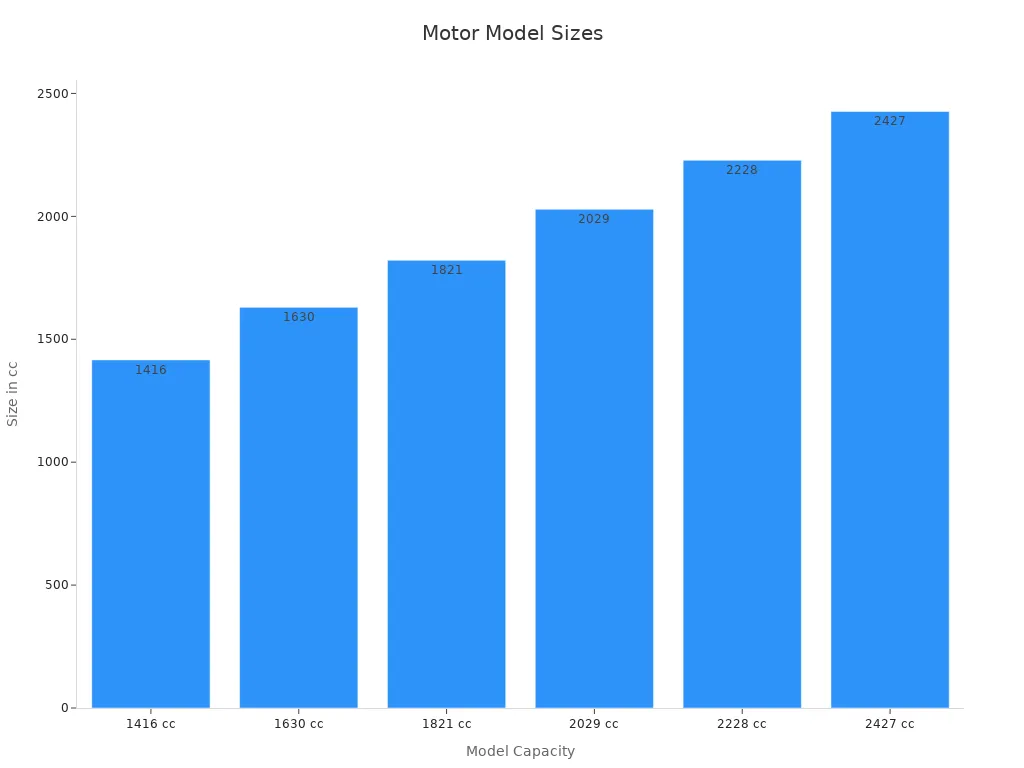

| Model Size | 1416, 1630, 1821, 2029, 2228, 2427 cc |

| Nominal Pressure | 350 Bar [5000 Psi] |

| Maximum Pressure | 500 Bar [7252 Psi] |

| Maximum Speed | 345 rpm |

| Power Output | Up to 200 kW |

| Applications | Marine, Construction, Agriculture, Mining, etc. |

These motors excel in demanding environments, such as marine propulsion systems, where reliability and efficiency are critical. Their energy-efficient design reduces operational costs and supports sustainability initiatives.

Eco-Friendly Hydraulic Fluids and Systems

Eco-friendly hydraulic fluids and systems are gaining traction in the marine industry due to their environmental benefits. Products like Bio-Fleet Hydraulic Fluids offer 100% biodegradability and low toxicity levels, ensuring compliance with EPA guidelines. These fluids exceed acute toxicity criteria, provide excellent water separation, and demonstrate improved thermal stability.

Product Name |

Biodegradability |

Toxicity Level |

Compliance with EPA Guidelines |

Performance Metrics |

|---|---|---|---|---|

| Bio-Fleet Hydraulic Fluids | 100% | Low | Yes | Exceeds acute toxicity criteria, excellent water separation, improved thermal stability |

Eco-friendly systems minimize environmental impact while maintaining high productivity. Their adoption aligns with sustainability goals and reduces the ecological footprint of marine operations.

- Characteristics of eco-friendly hydraulic fluids:

- Biodegradability ensures minimal environmental harm.

- Non-toxic formulations enhance safety for marine ecosystems.

- Improved thermal stability supports long-term performance.

Compact and Lightweight Designs

Compact and lightweight hydraulic motor designs simplify installation and improve vessel maneuverability. These designs reduce the overall weight of marine equipment, enhancing fuel efficiency and operational agility. Hydraulic motors with compact structures are particularly beneficial for applications requiring space optimization, such as luxury yachts and passenger ferries.

Operators benefit from reduced maintenance requirements and improved handling, making these designs ideal for modern marine vessels. The integration of lightweight materials further enhances durability and corrosion resistance, ensuring long-term reliability in harsh marine environments.

Smart Hydraulic Systems with IoT Integration

Smart hydraulic systems equipped with IoT integration are revolutionizing marine operations. These systems enable real-time monitoring and remote control, enhancing efficiency and safety. Operators can access performance data, identify potential issues, and optimize system settings from centralized platforms.

IoT-enabled hydraulic systems improve operational transparency and reduce downtime. Predictive maintenance features allow operators to address issues before they escalate, ensuring uninterrupted performance.

Key benefits of IoT integration include:

- Enhanced automation and control.

- Improved data-driven decision-making.

- Reduced human error during operations.

These systems represent the future of hydraulic technology, combining advanced automation with intelligent monitoring capabilities.

Two-Speed and Switchable Displacement Motors

Two-speed and switchable displacement motors offer unparalleled versatility in marine applications. These motors adapt to varying operational demands, providing high torque at low speeds and efficient performance at high speeds. The ability to switch displacement while the motor is running ensures seamless transitions between different modes.

Feature |

Description |

|---|---|

| Two-Speed Functionality | Enables high torque at low speeds and efficient performance at high speeds. |

| Switchable Displacement | Allows displacement changes during operation for optimal performance. |

| Control Mechanism | Realized with electro-hydraulic or mechanical control. |

These motors enhance energy efficiency and operational flexibility, making them ideal for applications such as fishing vessels and deck machinery. Their advanced design supports sustainability goals by reducing fuel consumption and emissions.

Benefits of Hydraulic Motor Innovations

Enhanced Fuel Efficiency and Cost Savings

Modern hydraulic motor innovations significantly improve fuel efficiency, leading to substantial cost savings for marine operators. Two-speed and switchable displacement motors optimize energy consumption by adjusting performance to match operational demands. This adaptability reduces fuel usage during low-load conditions while maintaining high torque when needed.

Additionally, advancements in hydraulic fluids contribute to energy efficiency. For instance, the Mobil DTE 10 ExcelTM Series demonstrates a 6% increase in hydraulic pump efficiency compared to standard fluids. Such improvements translate to lower fuel consumption and reduced operational expenses. By integrating these technologies, vessel operators can achieve long-term economic benefits while adhering to industry sustainability goals.

Reduced Environmental Impact

Innovative hydraulic systems play a crucial role in minimizing the environmental footprint of marine operations. Eco-friendly hydraulic fluids, such as the Mobil SHCTM 600 Series, enhance energy efficiency by 3.6% over conventional mineral oils. These fluids also exhibit superior biodegradability and low toxicity, ensuring minimal harm to marine ecosystems.

Hydraulic motors designed for high efficiency further reduce greenhouse gas emissions by lowering fuel consumption. The Mobil SHCTM Gear WT, for example, extends oil life, reducing oil consumption and maintenance frequency. These advancements align with stringent European environmental regulations, supporting the industry’s transition toward greener practices.

Tip: Adopting eco-friendly hydraulic systems not only meets regulatory requirements but also enhances a company’s reputation as a sustainable operator.

Improved Performance and Durability

Hydraulic motor innovations enhance performance and durability, ensuring reliable operation in demanding marine environments. High-efficiency motors deliver consistent power output, even under extreme conditions, while compact and lightweight designs improve maneuverability. These features make them ideal for applications ranging from fishing vessels to luxury yachts.

Durability is further reinforced through advanced materials and rigorous testing. For example, IP69K-certified motors undergo hydrostatic pressure and endurance tests to ensure resilience against harsh marine conditions. These innovations reduce downtime and maintenance costs, providing long-term operational reliability.

Advanced Automation and Control

Smart hydraulic systems with IoT integration revolutionize marine operations by enabling advanced automation and control. These systems allow operators to monitor performance in real time, identify potential issues, and optimize settings remotely. Predictive maintenance features minimize downtime by addressing problems before they escalate.

IoT-enabled systems also enhance data-driven decision-making. Operators can analyze performance metrics to improve efficiency and reduce human error. This level of automation not only streamlines operations but also ensures safety in hazardous environments. As a result, smart hydraulic systems represent a significant leap forward in marine technology.

Case Studies of Successful Implementations

High-Efficiency Motors in Fishing Vessels

Fishing vessels require reliable and energy-efficient systems to operate in demanding conditions. High-efficiency hydraulic motors have proven transformative in this sector. For example, a fleet of trawlers in Norway adopted two-speed hydraulic motors to power their winches and trawl systems. These motors provided high torque at low speeds, enabling precise control during fishing operations.

Key Outcome: The fleet reported a 20% reduction in fuel consumption and a significant decrease in maintenance costs due to the motors’ durability.

This implementation highlights how advanced hydraulic technology can enhance operational efficiency while supporting sustainability goals.

Smart Systems in Luxury Yachts

Luxury yachts demand cutting-edge technology to deliver seamless performance and comfort. Smart hydraulic systems with IoT integration have become a game-changer in this space. A leading yacht manufacturer in Italy incorporated IoT-enabled hydraulic motors to automate steering, stabilizers, and deck machinery.

- Features of the system:

- Real-time monitoring of hydraulic performance.

- Predictive maintenance alerts to prevent downtime.

These innovations improved the vessel’s reliability and enhanced the owner’s experience by ensuring smooth and uninterrupted operations.

Eco-Friendly Solutions in Passenger Ferries

Passenger ferries face strict environmental regulations, making eco-friendly hydraulic systems essential. A ferry operator in Denmark replaced traditional hydraulic fluids with biodegradable alternatives and upgraded to high-efficiency motors.

| Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Fuel Consumption | 1,200 liters/day | 950 liters/day |

| CO₂ Emissions | 3.2 tons/day | 2.5 tons/day |

This shift reduced the ferry’s environmental footprint and aligned its operations with European sustainability standards.

Custom Hydraulic Cylinders for Marine Applications

Custom hydraulic cylinders have enabled tailored solutions for unique marine challenges. A dredging company in the Netherlands collaborated with a hydraulic manufacturer to design cylinders capable of withstanding extreme underwater pressures.

Result: The custom cylinders enhanced the dredger’s efficiency, allowing it to operate at depths exceeding 200 meters without performance loss.

This case underscores the importance of customization in addressing specific operational needs in the marine industry.

Innovative hydraulic motor technologies are reshaping Europe’s boat industry by addressing critical challenges in efficiency, sustainability, and performance. Their adoption ensures competitive advantages and aligns with future trends.

Aspect |

Details |

|---|---|

| Market Growth | The hydraulic pumps market is expected to grow steadily in the coming decade due to advancements in digitally controlled hydraulic systems. |

| Energy Efficiency Demand | There is a growing demand for environmentally friendly and energy-efficient hydraulic systems. |

| Innovations Expected (2025-2035) | Innovations such as AI-based hydraulic optimization and zero-emission hydraulic solutions are anticipated to revolutionize the market. |

Stakeholders must embrace these advancements to secure a sustainable and competitive future.

FAQ

What makes two-speed hydraulic motors ideal for marine applications?

Two-speed hydraulic motors provide high torque at low speeds and efficient performance at high speeds. This adaptability ensures optimal energy use and operational flexibility in marine environments.

How do eco-friendly hydraulic fluids benefit marine operations?

Eco-friendly hydraulic fluids reduce environmental impact through biodegradability and low toxicity. They also enhance system efficiency and comply with stringent European environmental regulations.

Can IoT-enabled hydraulic systems improve vessel performance?

Yes, IoT-enabled systems allow real-time monitoring, predictive maintenance, and remote control. These features enhance operational efficiency, reduce downtime, and improve safety in marine applications.