Planetary Gearbox Basics and How They Work

Components of a Planetary Gearbox

Understanding the components of a planetary gearbox is crucial for grasping how it functions. Each part plays a vital role in the system’s operation. Let’s explore these components in detail.

Sun Gear

The sun gear sits at the center of the planetary gearbox. It serves as the primary driver of the system. When you apply torque to the sun gear, it transfers motion to the planet gears. This gear’s central position allows it to distribute power evenly. The sun gear’s size and number of teeth can affect the gearbox’s speed and torque output.

Planet Gears

Surrounding the sun gear, you find the planet gears. These gears rotate around the sun gear and within the ring gear. They play a key role in distributing the load across the system. By sharing the load, planet gears enhance the gearbox’s efficiency and durability. You often see multiple planet gears in a planetary gearbox, which helps balance the forces and reduce wear.

Ring Gear

The ring gear encircles the planet gears. It acts as the outermost component of the planetary gearbox. The ring gear’s teeth mesh with the planet gears, allowing them to rotate smoothly. This interaction helps modulate the gearbox’s speed and torque. The ring gear’s size and tooth count also influence the overall performance of the system.

How a Planetary Gearbox Works

Understanding how a planetary gearbox operates can deepen your appreciation for its engineering marvel. This section will guide you through the interaction of its components and how they modulate torque and speed.

Interaction of Components

In a planetary gearbox, the components work in harmony to achieve efficient power transmission. You start with the sun gear, which receives input torque. This gear transfers motion to the surrounding planet gears. As the planet gears rotate, they engage with the ring gear. This interaction creates a balanced distribution of forces. The planet gears revolve around the sun gear while also spinning on their own axes. This dual motion allows the planetary gearbox to handle high torque loads efficiently.

The ring gear, being the outermost component, plays a crucial role. It provides a stable boundary for the planet gears to rotate within. You will notice that the ring gear’s teeth mesh perfectly with the planet gears. This precise engagement ensures smooth operation and minimizes wear. The interaction among these components results in a compact and robust system. You benefit from a gearbox that delivers consistent performance in various applications.

Torque and Speed Modulation

A planetary gearbox excels in modulating torque and speed. When you apply torque to the sun gear, the system distributes it across the planet gears. This distribution reduces the load on individual gears, enhancing durability. You can achieve different speed ratios by altering the configuration of the gears. For instance, fixing the ring gear and driving the sun gear can increase output speed. Conversely, holding the sun gear stationary while rotating the ring gear can amplify torque.

The ability to modulate torque and speed makes the planetary gearbox versatile. You find it in applications requiring precise control over mechanical power. Whether in automotive transmissions or industrial machinery, this gearbox adapts to your needs. Its design allows for seamless transitions between different speed and torque settings. You gain the advantage of a system that optimizes performance without sacrificing efficiency.

Advantages of Planetary Gearboxes

Planetary gearboxes offer several advantages that make them a preferred choice in many mechanical applications. Understanding these benefits can help you appreciate why they are so widely used.

Compact Size

One of the standout features of a planetary gearbox is its compact size. You will find that this design allows for a high power-to-weight ratio. The arrangement of the sun gear, planet gears, and ring gear in a compact space enables efficient power transmission without taking up much room. This compactness makes planetary gearboxes ideal for applications where space is limited, such as in automotive transmissions and portable machinery. You can achieve significant power output from a relatively small unit, which is a major advantage in modern engineering.

High Efficiency

Efficiency is another key advantage of planetary gearboxes. You benefit from a system that minimizes energy loss during operation. The design ensures that power is transmitted smoothly between the gears, reducing friction and wear. This efficiency translates to lower energy consumption and longer service life for the gearbox. In applications where energy efficiency is crucial, such as in electric vehicles or renewable energy systems, planetary gearboxes provide an optimal solution. You can rely on them to deliver consistent performance while conserving energy.

Load Distribution

Load distribution is a critical factor in the durability and reliability of gear systems. A planetary gearbox excels in this area by evenly distributing the load across multiple planet gears. This balanced load sharing reduces stress on individual gears, enhancing the overall lifespan of the gearbox. You will notice that this feature also contributes to quieter operation, as the load is not concentrated on a single point. In heavy-duty applications like construction equipment or industrial machinery, the ability to handle high loads efficiently is invaluable. You gain a robust and reliable system that can withstand demanding conditions.

Applications of Planetary Gearboxes

Planetary gearboxes find applications in various fields due to their efficiency and compact design. You will discover their presence in several industries, where they play a crucial role in enhancing performance and reliability.

Automotive Transmissions

In the automotive industry, planetary gearboxes are essential components of transmissions. You benefit from their ability to provide smooth and efficient power transfer. These gearboxes allow for seamless gear shifting, which improves driving comfort and fuel efficiency. By using a planetary gearbox, you can achieve different speed ratios, which is vital for optimizing engine performance. This adaptability makes them a preferred choice in both manual and automatic transmissions. You will notice that many modern vehicles rely on planetary gearboxes to deliver a balanced combination of power and efficiency.

Industrial Machinery

Planetary gearboxes are also widely used in industrial machinery. You will find them in equipment that requires precise control over speed and torque. Their compact size and high efficiency make them ideal for applications where space is limited. In manufacturing processes, planetary gearboxes help maintain consistent performance, which is crucial for productivity. You can rely on them to handle high loads and operate under demanding conditions. This reliability ensures that industrial machinery runs smoothly, reducing downtime and maintenance costs. By incorporating planetary gearboxes, industries can enhance their operational efficiency and output quality.

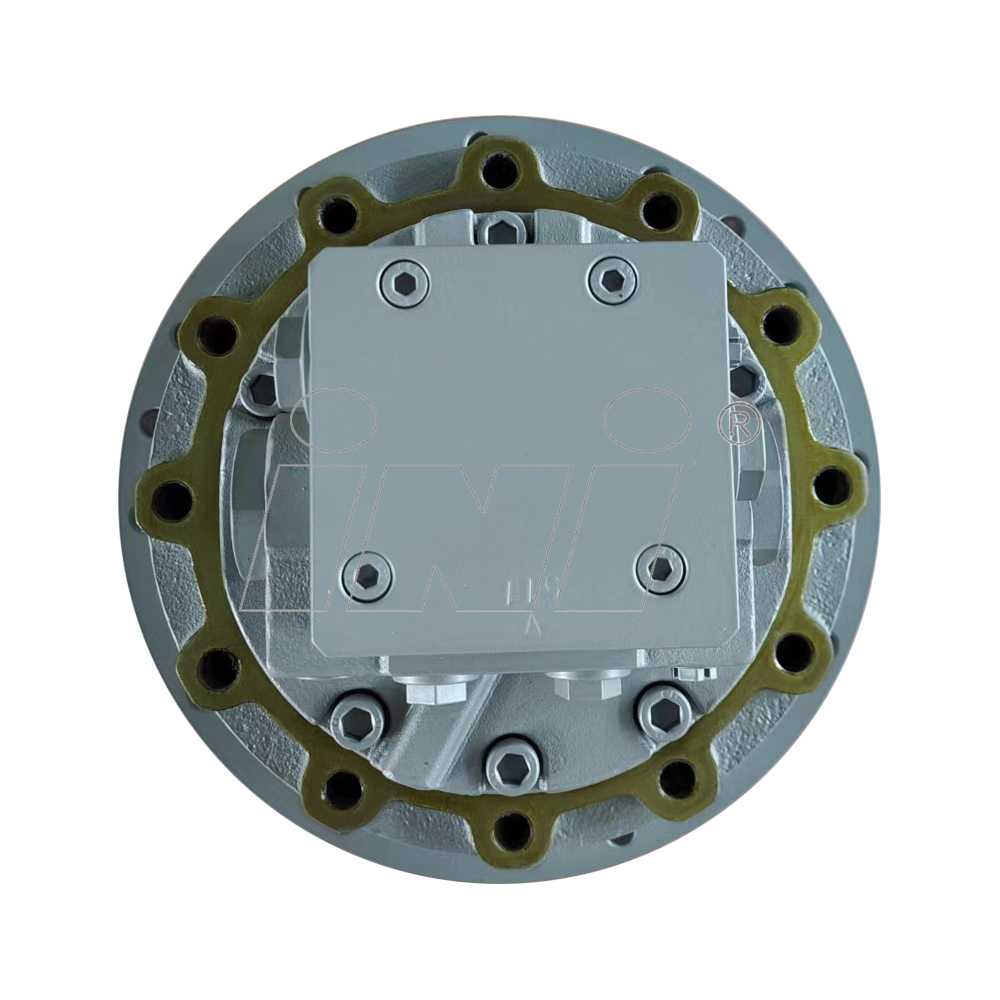

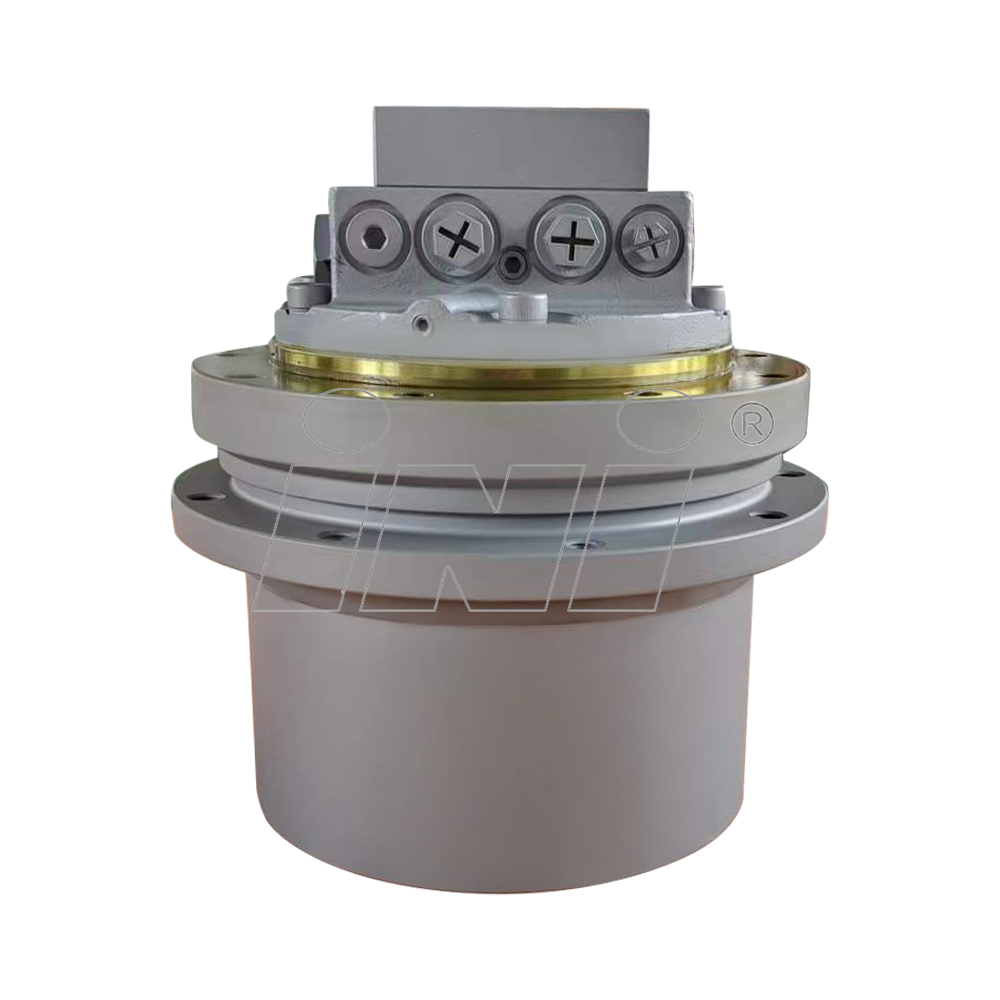

Construction and Off-shore Equipment

In construction and off-shore equipment, planetary gearboxes play a vital role in handling heavy loads. You will see them in cranes, excavators, and other machinery that require robust power transmission. Their ability to distribute load evenly across multiple gears enhances durability and performance. This feature is particularly valuable in environments where equipment faces harsh conditions. By using planetary gearboxes, you can ensure that construction and off-shore machinery operates efficiently and withstands the rigors of the job site. Their compact design also allows for easy integration into various types of equipment, making them a versatile choice for engineers and designers.

You now understand the essential components of a planetary gearbox: the sun gear, planet gears, and ring gear. These parts work together to transmit torque and modulate speed efficiently. The compact size and high efficiency of planetary gearboxes make them invaluable in various applications. You see their importance in automotive transmissions, industrial machinery, and construction equipment. By choosing planetary gearboxes, you benefit from reliable performance and enhanced durability. This knowledge empowers you to appreciate the engineering marvel behind these versatile systems.

See Also

Tips for Keeping Your Hydraulic Winches in Top Shape

Comparing Hydraulic and Electric Winches for Marine Use

Zhejiang Introduces New Certification Standards for Hydraulic Winches

Preventing Cavitation Issues in Your Hydraulic System

PTC ASIA 2019: Launch of Innovative Man-Carrying Hydraulic Winches