What is the hydraulic system?

A hydraulic system uses pressurized fluid to transmit power and perform mechanical work. It converts mechanical energy into fluid power, then back into movement. Engineers rely on principles like the Navier-Stokes equations and the Darcy-Weisbach formula to optimize hydraulic system design, as shown in any detailed hydraulic system diagram.

Key Takeaways

- Hydraulic systems use pressurized fluid to multiply force and perform heavy tasks with precise control, based on Pascal’s Law.

- Key parts include pumps, reservoirs, valves, actuators, and fluid, each essential for efficient power transmission and control.

- Hydraulic systems power many industries by offering high force, energy efficiency, and reliability, but they need regular maintenance to avoid leaks and contamination.

How a Hydraulic System Works

Basic Principles of Hydraulic System (Pascal’s Law)

A hydraulic system operates based on Pascal’s Law, a fundamental principle in fluid mechanics. Pascal’s Law states that when pressure is applied to a confined fluid, the pressure is transmitted equally in all directions throughout the fluid. This principle allows hydraulic systems to multiply force and perform heavy lifting with minimal input.

For example, when a person applies a force to a small piston, the pressure generated in the fluid travels through pipes and hoses to a larger piston. The larger piston, having a greater surface area, produces a much larger output force. The relationship between input and output force depends on the ratio of the piston areas. If the input piston has an area of 2 square centimeters and the output piston has an area of 20 square centimeters, the output force will be ten times greater than the input force, assuming the same pressure is applied.

Pascal’s Law enables hydraulic systems to use pipes and containers of various shapes without losing pressure, making them highly adaptable for different mechanical applications.

This principle forms the basis for devices such as hydraulic presses, car brakes, and construction machinery. The ability to transmit pressure uniformly allows engineers to design systems that can lift vehicles, operate heavy equipment, and provide precise control in industrial settings.

Step-by-Step Operation of a Hydraulic System

The operation of a hydraulic system involves several key steps, each contributing to the efficient transfer and control of power. The following sequence outlines the typical process:

- Energy Input: The system begins with a mechanical input, such as an electric motor or engine, which drives a hydraulic pump.

- Fluid Pressurization: The pump draws hydraulic fluid from a reservoir and pressurizes it, creating a flow of fluid under high pressure.

- Transmission of Pressure: Pressurized fluid travels through hoses and pipes to various components, such as valves and actuators.

- Control and Direction: Valves regulate the direction, pressure, and flow rate of the fluid, allowing precise control over the movement of actuators.

- Mechanical Output: Actuators, such as cylinders or hydraulic motors, convert the fluid power back into mechanical movement, performing tasks like lifting, pushing, or rotating.

- Return Flow: After completing its work, the fluid returns to the reservoir, ready to be recirculated by the pump.

Technicians often use diagnostic tools, including pressure gauges and digital multimeters, to monitor system parameters such as pressure levels and electrical characteristics. If measurements indicate irregularities, they may inspect internal components for wear or damage. This approach combines quantitative data with visual inspection to ensure optimal system performance.

Experimental studies have shown that hydraulic systems can achieve significant energy savings and improved efficiency with advanced control technologies. For instance, circuits using flow control valves can reduce energy consumption by over 15% at no load and nearly 10% at higher loads. Temperature measurements also reveal that efficient systems operate at lower temperatures, which enhances sustainability and reduces wear.

Industry standards, such as ISO 4409:2007, provide guidelines for testing and validating the efficiency of hydraulic pumps and motors. These standards ensure that manufacturers and engineers can rely on accurate, repeatable data when selecting and maintaining system components.

Note: Understanding the step-by-step operation and the underlying principles of a hydraulic system helps engineers design reliable and efficient machinery for a wide range of applications.

Main Components of a Hydraulic System

A hydraulic system relies on several essential components, each playing a specific role in power transmission and control. Understanding these parts helps engineers design efficient and reliable machinery.

Hydraulic Pump

The hydraulic pump converts mechanical energy into hydraulic energy, creating the flow of pressurized fluid that powers the system. Common pump types include gear, vane, and axial piston pumps. Modern pumps offer high efficiency, with some models achieving over 92% efficiency and operating pressures up to 420 bar (6090 psi). Advanced electronic controls allow precise adjustment of flow and pressure, making these pumps suitable for demanding industrial and mobile applications.

| Parameter | Specification / Measurement |

|---|---|

| Displacement Range | 10 cm³/rev to 250 cm³/rev |

| Maximum Operating Pressure | Up to 420 bar (6090 psi) |

| Efficiency | Above 90% |

| Torque Ratings | Up to 800 Nm |

| Control Options | Electronic controls for flow and pressure |

Reservoir

The reservoir stores hydraulic fluid and allows air bubbles to escape. Traditional designs use large tanks, often three to five times the maximum pump flow. Modern reservoirs use compact designs, sometimes only matching the pump flow, which reduces weight and floor space by up to 80%. These innovations improve system efficiency and lower oil volume requirements.

| Metric Aspect | Traditional Reservoir | Modern Reservoir |

|---|---|---|

| Size Ratio | 3–5x pump flow | 1:1 with pump flow |

| Example Capacity | 600 liters | 150 liters |

| Footprint | 2 m² | 0.5 m² |

| Weight | Baseline | Up to 80% lighter |

Valves

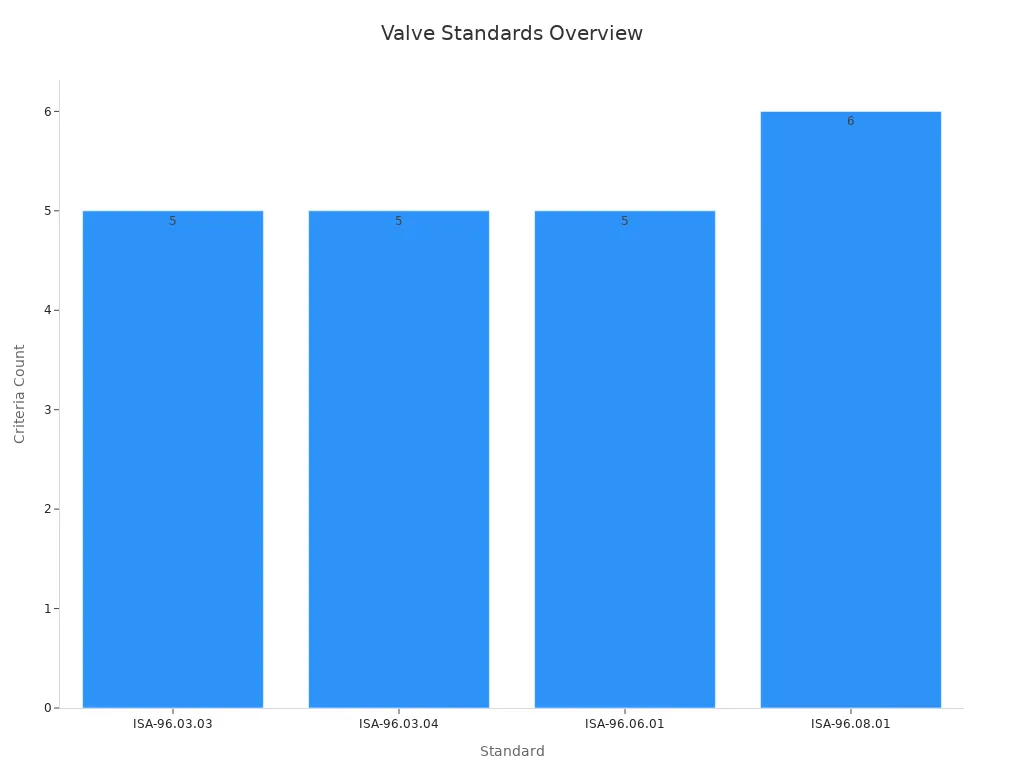

Valves control the direction, pressure, and flow rate of hydraulic fluid. Types include pressure, directional, and flow valves. Engineers use quantitative methods like partial stroke testing and in-situ proof testing to ensure valve reliability and safety. Modern standards, such as ANSI/ISA-96.06.01-2022, define performance criteria for valve actuators, including diagnostics and safety.

Actuators (Cylinders and Motors)

Actuators transform hydraulic energy into mechanical motion. Hydraulic cylinders produce linear movement, while hydraulic motors create rotary motion. These components deliver high force outputs, with some cylinders generating up to 43,000 lbf. Electro-hydraulic actuators improve efficiency and can reduce energy consumption by over 50% through energy regeneration.

Hydraulic Fluid

Hydraulic fluid transmits power, lubricates components, and removes heat. The fluid’s viscosity affects efficiency, lubrication, and heat generation. Engineers select fluids based on system requirements, temperature range, and pump type. Additives like anti-wear agents and rust inhibitors protect system parts and extend fluid life. Proper fluid selection ensures optimal performance and reliability for any hydraulic system.

Hydraulic System Applications, Advantages, and Comparisons

Common Applications of Hydraulic System

Hydraulic systems power a wide range of industries. Construction, agriculture, aerospace, automotive, and material handling all rely on these systems for heavy lifting and precise control. For example, Pennar Industries plans to produce 150,000 hydraulic cylinders annually for agriculture and construction. The Polavaram irrigation project uses 96 hydraulic cylinders to operate 48 radial gates. The table below highlights the scale and diversity of applications:

| Aspect | Details |

|---|---|

| Production Volume | 150,000 hydraulic cylinders annually (agriculture, construction) |

| Largest Revenue Segment | Cylinders (agriculture, automotive, construction, material handling) |

| Example Project | Polavaram irrigation: 96 cylinders for 48 gates |

| End-Use Industries | Construction, agriculture, aerospace, automotive, metal & machinery, oil & gas |

| Technology Integration | IoT, electro-hydraulic valves, software-controlled systems |

Industry 4.0 technologies like IoT and AI now enhance productivity by 15% in smart hydraulic solutions.

Advantages of Hydraulic System

Hydraulic systems deliver high force output, precise control, and reliability. Kawasaki systems, for instance, offer energy efficiency and smooth power delivery. Modular designs allow customization and space savings. In agriculture, precision farming increases crop yields. Construction equipment achieves up to 25% fuel savings with hydraulic hybrids. Electrohydraulic actuators in aerospace provide accurate control of aircraft surfaces. New synthetic fluids and digital controls further improve reliability and sustainability.

Tip: Machine learning and predictive maintenance reduce downtime and optimize performance in modern hydraulic systems.

Disadvantages of Hydraulic System

Hydraulic systems require regular maintenance due to fluid contamination and leak risks. Leaks can cause environmental issues and increase disposal costs. Compared to pneumatic systems, hydraulics operate at slower speeds and need more complex maintenance. Water-based fluids reduce leakage costs but demand specialized components, which can raise expenses.

Hydraulic System vs. Pneumatic System

| Aspect | Hydraulic Systems | Pneumatic Systems |

|---|---|---|

| Operating Pressure | 1,000–10,000+ psi | 80–100 psi |

| Force Output | Up to 25× greater | Lower, due to compressible air |

| Speed | Slower, more precise | Faster, less precise |

| Energy Efficiency | Higher for continuous loads | Lower, higher operating costs |

| Maintenance | More demanding | Easier, mainly air quality |

| Safety | Fluid leaks pose risks | Safer, uses non-toxic air |

| Cost | Higher initial and maintenance | Lower upfront, higher operating over time |

Hydraulic systems excel in high-force, precision tasks, while pneumatic systems suit rapid, moderate-force applications.

A hydraulic system uses pressurized fluid to move heavy loads and control machinery. Engineers value its reliability and adaptability. Key components include pumps, reservoirs, valves, actuators, and fluid. Industries such as construction, agriculture, and aerospace benefit from its high force, precise control, and energy efficiency.

FAQ

What type of fluid do hydraulic systems use?

Most hydraulic systems use specially formulated oil. This oil resists corrosion, lubricates parts, and operates efficiently under high pressure.

How often should technicians replace hydraulic fluid?

Technicians should check fluid condition regularly. Most systems require fluid replacement every 1,000 to 2,000 operating hours, depending on manufacturer recommendations.

Can hydraulic systems operate in extreme temperatures?

Yes. Engineers select fluids and components designed for specific temperature ranges. Proper selection ensures reliable performance in both hot and cold environments.