Special Design for Mini Lift Concrete Hoists Small Building Elevator Winch

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Special Design for Mini Lift Concrete Hoists Small Building Elevator Winch, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Mini Lift Concrete Hoists Small Building Elevator Winch, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This hoisting winch is one of the trademark products of the reliability proof of our products. For satisfying high-reliability demands of person lift winches, compared to the existing solutions, we have invented an advanced form of braking system, which innovated with two multi-plate disc normally closed brakes at the high-speed stage and the last stage of the gearbox respectively.

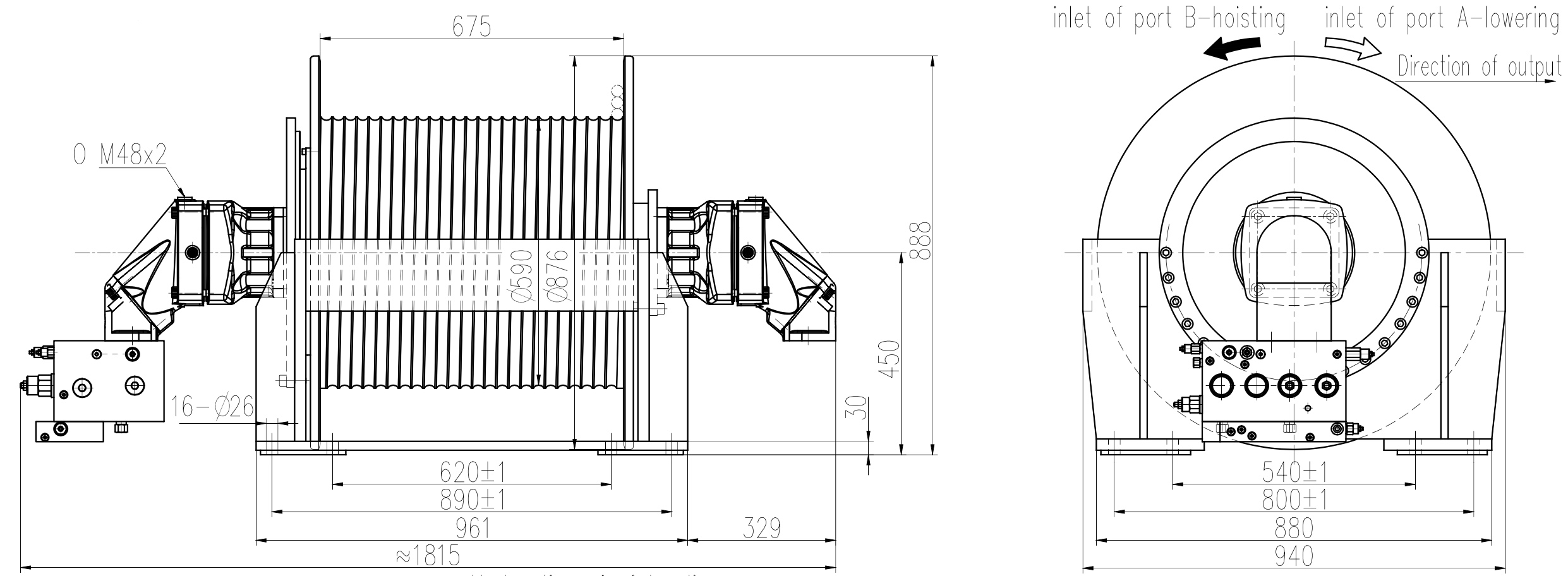

Mechanical Configuration: The winch consists of two hydraulic motors, one planetary gearbox, two multi-disc brakes, valve blocks, drum and frame. Customized modifications are available at any moment.

The Winch’s Main Parameters:

| Working Condition |

Carry Cargo |

Man Riding |

| Rated Pull at the 3rd Layer (t) |

13 |

2 |

| Max Line Pull at the 3rd Layer (t) |

14 |

2.5 |

| Rated System Pressure (Bar) |

280 |

60 |

| Max System Pressure (Bar) |

300 |

70 |

| Speed of Cable Wire at the 3rd Layer (m/min) |

120 |

|

| Total Displacement (mL/r) |

13960 |

|

| Pump Supply Oil Flow (L/min) |

790 |

|

| Diameter of Care Wire (mm) |

26 |

|

| Layer |

3 |

|

| Drum Capacity of Care Wire (m) |

150 |

|

| Hydraulic Motor Model |

F12-250×2 |

|

| Gearbox Model (Ratio) |

B27.93 |

|

| Static Brake Holding Force at the 3rd Layer (t) |

19.5 |

|

| Dynamic Brake Holding Force at the 3rd Layer(t) |

13 |

|

| High Speed Stage Brake Torque (N.m) |

2607 |

|

| Low Speed Stage Brake Torque (N.m) |

50143 |

|

| Brake Control Pressure (Bar) |

>30, <60 |

|

Special Design for Mini Lift Concrete Hoists Small Building Elevator Winch Related Video: