Hydraulic Winch – 50KN

Hydraulic winch – IYJ355-50-2000-35DP is well built based on our patented technology. The mechanism of the winch is meticulously designed to accomplish its expected mission. The strength of its materials and structure is thoroughly calculated. The angle self-feedback adaptive cable arrangement mechanism is integrated organically to build up the winch body, which is appreciated greatly because of its efficient and reliable performance. It features high-efficiency, low-noise, high-power, energy conservation, compact structure and cost-efficiency. The winches are widely applied in construction machinery, petroleum machinery, mining machinery, drilling machinery, ship and deck machinery.

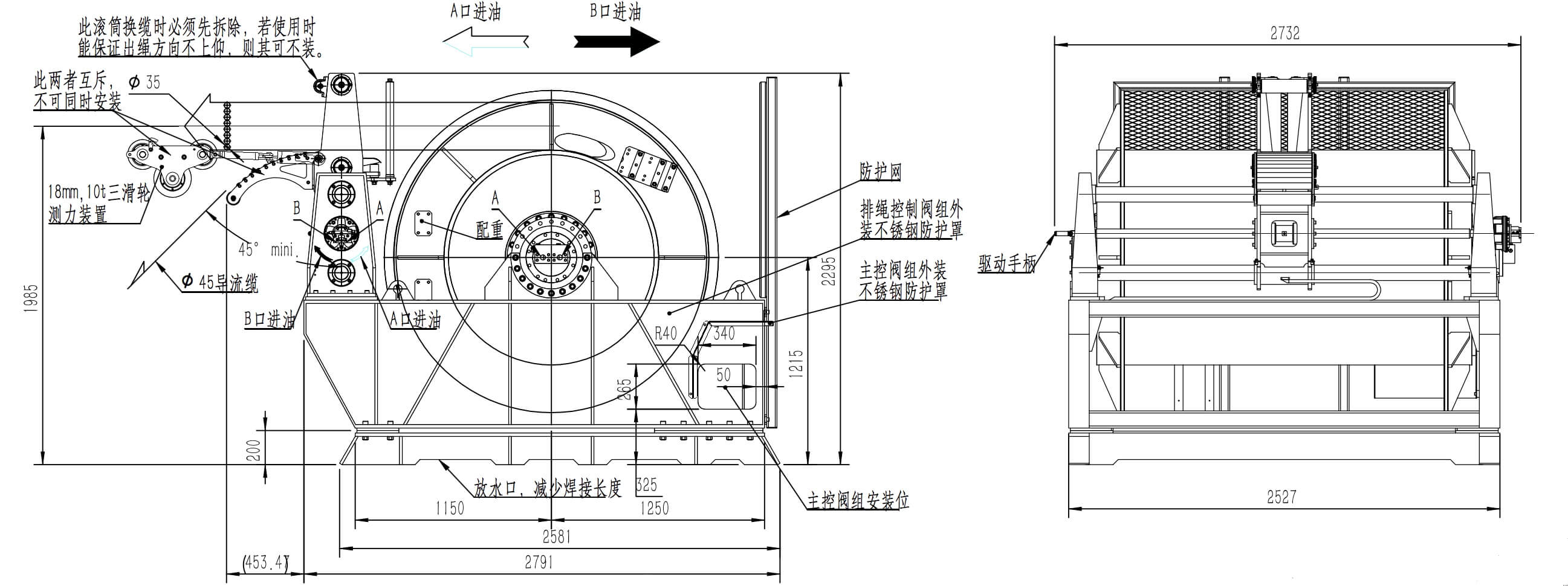

Mechanical Configuration: The winch consists of valve blocks, hydraulic motor, Z type brake, KC type or GC type planetary gear box, drum, frame, brake, protection board and automatically arranging wire mechanism. Customized modifications for your best interests are available at any moment.

The Hydraulic Winch‘s Main Parameters:

| The 4th Layer |

Low-speed |

High-speed |

| Rated Pull(KN) |

50 (Ø35 wire) |

32 (Ø35 wire) |

| Rated Speed of Wire (m/s) |

1.5 (Ø35 wire) |

2.3 (Ø35 wire) |

| Rated Speed of Drum (rpm) |

19 |

29 |

| Layer |

8 |

|

| Drum Size: bottom radius x Protection Board x Width (mm) |

Ø1260 x Ø1960 x 1872 |

|

| Wire Length (m) |

Ø18 x 2000, Ø28 x 350, Ø35 x 2000, Ø45 x 160 |

|

| Wire Diameter (mm) |

18, 28, 35, 45 |

|

| Reducer Type (with motor and brake) |

IGT80T3-B76.7-IM171.6/111 |

|

| Hydraulic Motor for Wire Arrangement Device |

INM05-90D31 |

|

| Wire Arrangement Device | Angle Self-feedback Adaptive Wire Arrangement | |

| Clutch |

Non |

|

| Working Pressure Difference (MPa) |

24 |

|

| Oil Flow (L/min) |

278 |

|

| Toal Transmission Ratio |

76.7 |

|